Cuisinart Top Interlock Repair

We got our first Cuisinart in 1982. It served us well for more than a decade so when it finally gave up the ghost we purchased another one. We were dismayed to find that the new Cuisinart Custom 14 had changed the interlock on the mixing bowl and top. There was now an additional tab so that the large plunger had to be in place and you were limited to the 2 inch diameter hole for feeding to process while the machine was running. It was annoying but we lived with it. But the plastic tab on this complicated interlock eventually broke. So we decided to design a 3-D printable replacement part that would return the operation to the way the old-style Cuisinart worked.

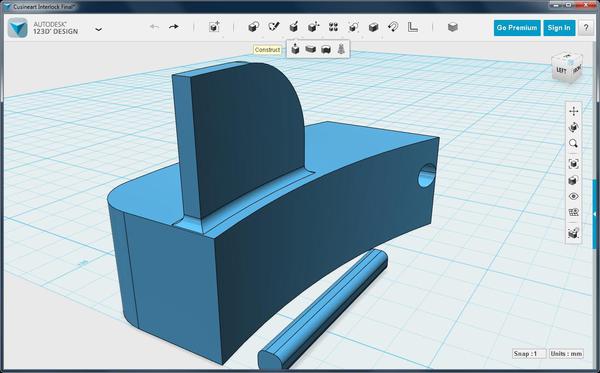

I removed the broken interlock tab and drew a sketch of its dimensions. I sat down at the computer with Autodesk’s 12 3-D Design and created a part that would fit where the old tab was but not engage with the plunger interlock pin.

Once I completed the design of the part I exported it as an STL file.

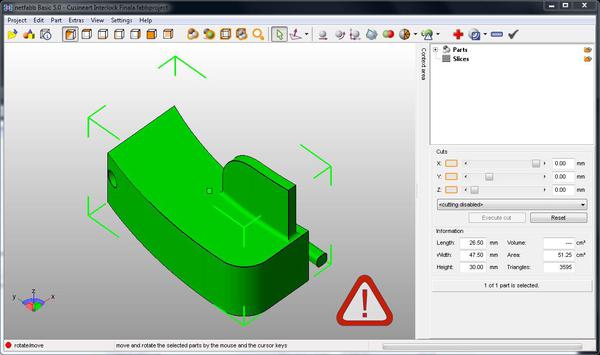

However the part had some errors and was not interpreted correctly by Slic3r. So I loaded the part into Netfabb and re-exported it. That seemed to repair the errors.

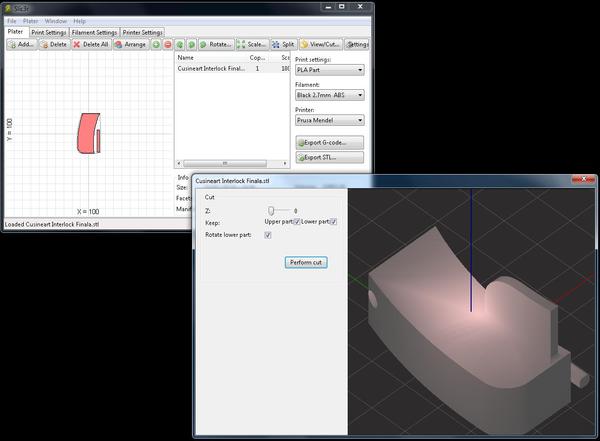

I brought the part into Slic3r, which I set up for ABS plastic, 10% infill, three layers tops and sides, and 35% fan RPM for layers that would take less than 30 seconds to print. That last setting is necessary to get a clean fin on top of the block. I printed in ABS because sometimes these parts go through the dishwasher and I think ABS should be able to withstand those temperatures. PLA most likely would not.

The part took about 40 minutes to print, and it fit in place beautifully. I also printed out a plastic pin to retain it.

If you want to print out your own parts The printed part has a hole in it so the interlock plunger has no effect and the Cuisinart can be turned on with the entire chute open. You could conceivably put your hand in there and cut it to shreds, this was indeed the case with the old model Cuisinart. While the new model is safer, it is much harder to do things like slice potatoes with the new style machine. We are entirely comfortable with this safety third approach, but your mileage may vary and you should act accordingly.

If you want to print your own parts the 123D Design source file is here. And the STL file is here.

Would you be willing to print one of these tabs for me? I would pay you of course.